Architecturally Exposed Structural Steel

The AESS Categories - AESS3 - Feature Elements (≤ 6m)

AESS 3 – Feature Elements includes structures that will be viewed at a distance ≤ 6m. The Category would be suitable for "feature" elements – where the designer is comfortable allowing the viewer to see the art of metalworking. The welds should be generally smooth but visible and some grind marks would be acceptable. Tolerances must be tighter than normal standards. As this structure is normally viewed closer than six meters it might also frequently be subject to touch by the public, therefore warranting a smoother and more uniform finish and appearance. This type of structure could be found in airports, shopping centres, hospitals or lobbies and could be expected to incur a moderate cost premium that could range from 60% to 150% over Standard Structural Steel as a function of the complexity and level of final finish desired.

|

|

The Canadian War Museum in Ottawa uses AESS to create a highly articulated and rugged expression in the steel in Regeneration Hall. In this instance a combination of welded connections and exposed plate to plate moment connections at the connection points between square HSS sections is the feature of the appearance. Due to the irregularity of the structure, tight tolerances are required. The profiled decking is also left exposed to view. |

In the Canadian War Museum there are exposed welded and bolted connections. Square plates have been welded to the HSS members that provide surface for bolts on all sides of the connection to ensure a uniform appearance. Flat plates have been used for the lap type hinge connections on the diagonal members, creating a degree of uniformity within the scheme. Overall the connection methods are simple variations of standard connections and do not result in excessive premiums. |

When AESS structural elements are brought into close range for view as well as potentially for touch, it is necessary for the team to come to a clear understanding about the level of finish that is both required and expected of the steel. The natural look of welds that would be out of view in AESS 2 steel will now be visible to the occupant in the space. Simple bolted connections may need to be designed to look more artful if they are to become part of the language of the architecture. Connections will come under closer scrutiny, so their design, tolerances and uniform appearance will become more important and the workmanship required to improve these beyond both Standard Structural Steel and AESS 1 and 2 could have a significant impact on the cost of the overall structure. If the required attributes or characteristics of the steel are not thoughtfully considered, the AESS for the project can easily be priced higher.

|

|

The Palais des Congrès in Montreal uses specialty W sections with trimmed cutouts. Although the steel is all painted grey, and intumescent coatings are used, the coloured light through the curtain wall gives additional texture to this expression of steel. |

This detail on the Millennium Dome in London, England by Richard Rogers, puts the AESS in direct contact with the public. A higher level of workmanship is required due to the proximity of view. |

The cost premium to be found in AESS 3 steel will depend greatly upon the types of members chosen, the nature of the connections, and the desire of the designer to either conceal or express the materiality of the steel itself. As can be seen later in this document under Characteristics, it is assumed that effort will be put into further preparation of the surface to increase its smoothness to ensure that some of the natural finish on the steel and mill marks do not show through the paint.

There may be more welded connections in AESS 3 steel. Where welds cannot be done in the shop, where conditions are more controlled and jigs can be used to ensure precise alignment of the components, it must be realized that large amount of site welding of complex elements will result in cost premiums. Some site welds may not be of the same quality as can be expected of shop welds. It would be expected that the welds would be of a higher quality than those for AESS 2 structures where the welds would be out of view and touch due to their height. AESS 3 welds will be expected to have a very uniform appearance. Although some touch up grinding of the welds may be required to ensure uniformity, complete grinding of all welds would not be included in this category of steel. It is assumed that good quality, uniform welds would be left exposed.

Where bolted connections are employed more care will be taken to ensure that there is an aesthetically based uniformity in the connections that will likely require more fabrication time and potentially more material. Simple approaches such as ensuring all bolt heads are located on uniform sides of the connections can greatly enhance the details with little extra cost. If bolted connections are required for erection ease, but are visually unacceptable, concealed connections can be employed to give the appearance of a seamless or welded connection, without the associated price tag. For these types of connections the attaching plates are kept within the general "line" of the members so that cover plates can be attached over the bolted elements. If this is to be an exterior application, concealed connections must be made corrosion resistent to prevent hidden rust.

Underlying AESS 3 steel is the idea that it is possible to change the appearance of the final product to make it smoother to the eye, but it is not always necessary to use more expensive fabrication techniques to arrive at this point. As will be seen under Characteristics, it is possible to use simpler methods to surface fill or provide the appearance of a continuous weld without actually welding.

AESS3 - Characteristics

This increased proximity of viewing distance of this Category begins to place the evidence of certain fabrication processes into close viewing range. Where some of the natural evidence of the materiality and connection methods of steel might be acceptable at a greater viewing distance, the same might not be acceptable "up close" where the final product can be both viewed and touched. In many cases these markings will need to be carefully positioned so that they can not be seen, removed, or concealed.

|

|

|

3.1 Mill marks removed. Courtesy of AISC |

Depending on the location of the element and the mill marks, these can also be made to be less noticeable by virtue of location or orientation. |

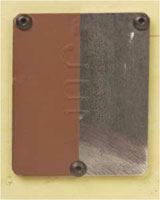

3.2 Butt and plug welds ground smooth. Right side shows groove weld ground smooth. Courtesy of AISC |

3.1 The Mill marks are to be removed as not to be visible in the finished product. Removal of these marks would typically be accomplished by grinding.

3.2 Butt and plug welds are to be ground smooth and filled to create a smooth surface finish. Caulking or body filler is acceptable.

These kinds of welds can result in the presence of additional material or slight depressions in the members. These imperfections will be visible after finishing. If additional material is present it should be ground smooth. If there are depressions, the voids can be filled with body filler and the surface ground smooth prior to finish applications.

3.3 The normal weld seam that is the product of creating HSS shapes is to be oriented for reduced visibility. In general the seams are to be oriented away from view in a consistent manner from member to member, or as indicated in the Contract Documents.

Welded seams are a natural finish appearance that are part of the manufacturing process of HSS members. When choosing HSS this is important to bear in mind. A seamless finish is not possible without significant added expense and time. There are other options to grinding the seams. The seams can be consistently located to give a uniform appearance. If HSS seams are able to be oriented away from direct view, this is an acceptable solution. If the seams are located in members whose viewing angles are multiple, then greater care must be taken in detailing the members to achieve a consistent look. If two HSS members are joined (see Fig 3.3A) then ensure that the weld seams are aligned.

|

|

3.3 The weld seams on these connecting HSS sections may have been better detailed if they had been aligned. |

3.4 This column splice has not managed to be erected/detailed so that all of the abutting surfaces align. |

3.4 Cross sectional abutting surfaces are to be aligned. The matching of abutting cross-sections shall be required. Offsets in alignment are considered to be unsightly in these sorts of Feature Elements at a close range of view.

Part of this characteristic may be helped by ensuring that the steel conforms to Characteristic 2.2, half standard tolerances, but this will not guarantee completely precise alignment of abutting members - particularly when using "off the shelf" structural sections that will have had little specialty fabrication work done to them (see Fig. 3.4). There may also be need to shape or grind the surfaces at the point of connection to ensure that the surfaces are aligned. In some lighting conditions shadow casting may be more problematic than others. Where the inconsistencies are small, be sure to incorporate advanced knowledge of the final finish coat as it may either help to conceal or exacerbate these slight misalignments.

|

|

Joint gap minimized. The gaps on the left are standard structural steel. On the right sized for AESS. Courtesy AISC |

This exposed bolted connection is tightly designed and demonstrates uniformity in the joint gaps. |

3.5 Joint gap tolerances are to be minimized. This Characteristic is similar to 2.2. A clear distance between abutting members of 3 mm is required.

The use of bolted connections is quite common in many AESS applications. Bolted connections may be advantageous for erection purposes or constructability, and might also suit the aesthetic of the project. In keeping with tighter tolerances on the members themselves, the reduction of joint gaps in bolted connections aids in ensuring consistency and tighter design.

3.6 AESS 3 Feature Elements may require all welded connections. This is noted as optional; acknowledging that a particular aesthetic might purposefully choose bolted connections.

Much of the overall aesthetic intention of a project is held in the decision to use an all welded structure over one that either uses some or all bolted connections. Welded connections are easier to fabricate in the shop. The erection condition on the site might require temporary shoring to hold the geometry in place while welding is completed. There may be additional work to repair the surfaces that have been damaged due to the removal of the temporary steel such as backing bars.

In some situations, whether due to access constraints or issues of time, welded connections might not be possible. Alternatively if an entirely welded appearance is desired, hidden bolts may be considered as an acceptable solution. A bolted connection is concealed behind the cover plate. If this connection is used in an exterior environment, care must be taken to seal the joint to prevent water from becoming trapped.

|

|

3.6 This connection desired for a seamless connection between two large square HSS sections. It is quite different in appearance from the connection to the right - both being all welded - as a result of the finishing that was specified. |

This design at The Pritzker Pavilion in Chicago by Frank Gehry used all welded connections, even for this anchoring detail of the truss to the base plate. Bolted connections were not desired. |